Lifestyle

The most effective method to choose the right laser cutting equipment

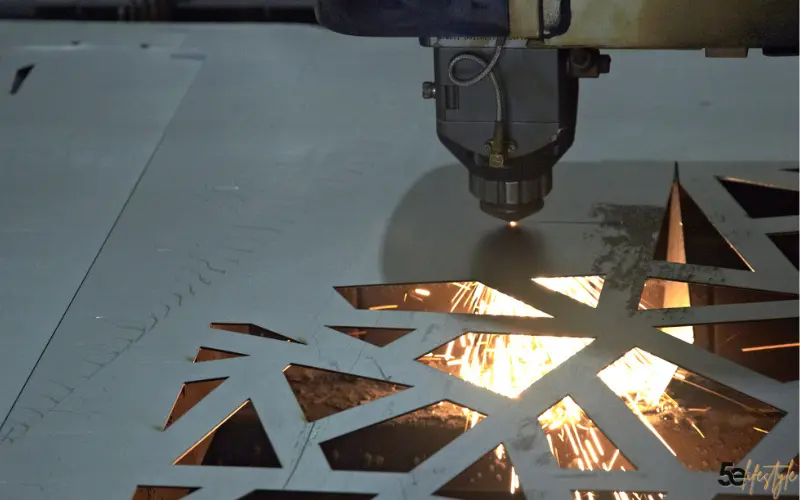

A laser cutter is a very supportive and flexible device. Laser cutting is the strategy for utilizing serious areas of strength for a compelling laser to one or the other engrave or cut materials like wood, plastic, metal, and aluminum.

Laser cutters work by controlling an incredibly powerful laser beam that precisely engraved or cuts the material. The laser cautiously melts or burns away the material and passes on an exact shape because of the slight shaft that is delivered

In spite of the fact that laser cutting has been open and usable throughout recent decades, there actually is by all accounts befuddled about which kind of laser cutting is adequate for every application strategy.

Table of Contents

Do I want a laser cutter?

There are a couple of choices to consider prior to concluding that you really want to buy your own laser cutter.

One of the main choices to consider is to get to a nearby, laser cutting machine. Many spots including neighborhood colleges approach shared laser cutters. These spots furnish the nearby local area with laser cutters through a month-to-month membership or by recruiting the machine continuously. It is critical to note, nonetheless, that there are unmistakable experts.

Pros:

One of the most sizable stars of a laser cutting machine is that you do not just get to the machine and every significant instrument; however, you can likewise get into contact with similar individuals. This ace is extremely valuable as you might have the option to learn new and more effective approaches to cutting and even inclines a few hints en route.

Another star is that you don’t need to set aside and convey an underlying capital venture. Setting aside the assets to buy a machine can take a significant measure of time.

A significant expert is that you need to play out no support on the machine.

One more expert of utilizing a laser cutting machine is that the machine might have more power and scope of capacities that you might not have had the option to bear in the event that you purchased a machine all alone.

What to consider:

Before you decide the elements of what sort of laser cutter you want, there are evaluations that you want to make on what your necessities are.

The first is to evaluate what kind of material you will be cutting as this will straightforwardly influence your decision on the laser cutter. Laser cutters can be utilized for a large number of materials like wood, metal, plastic, acrylic, and aluminum. You will require a wood laser cutting machine if you wish to cut cardboard or wood.

The following need that you really want to consider is the size of the crude and immaculate material that you will cut. This is significant as fluctuating lasers have various sizes of beds. For instance, assuming you will be cutting blocks, you really want to guarantee that the blocks can fit under your laser so they can cut precisely. When in doubt, your laser ought to have a bed that is bigger than the size of the eventual outcome.

Albeit most laser cutting work is finished on a sheet of your preferred material, there are a few ventures that include cylindrical materials. To work with materials and items, for example, glasses and containers, you will require a cutter that upholds a borer. This device permits you to clutch materials in a chamber shape and turns them in a like manner with the goal that the whole surface can either be cut or engraved.

One more need that you want to consider while attempting to decide the kind of laser cutter gear that you ought to put resources into is whether the sort of work that you will perform will be cutting, engraving, or both. The sort of work that you will perform will assist you with finishing up how much power you require.

Assuming you have evaluated your necessities and have confirmed that you will buy your own laser cutting machine, there are a couple of variables that you first need to consider on the most proficient method to pick the right piece of hardware. It is critical to take note of that except if you have limitless assets, there are trade-offs that you might have to make.

Cost is quite possibly the most central factor in the kind of laser cutting hardware you can choose. Laser cutters can change in cost unfathomably.

The following element that you really want to consider is the power result of the laser. Customarily, the more noteworthy the force of the laser cutter, the more thick the material that the machine can cut, and the more rapidly it can finish this job. The capacities of the machine are different for each power level.

Read here for more related content: thurstportal