Lifestyle

About the process of metals cutting, how much do You Know?

Understanding the advancement of metal cutting incorporates finding out about metal properties and their various verifiable applications.

History expresses that prehistoric man knew all about six metals

He found that every metal had novel properties, in this way requiring different manipulation methods, and in the long run, different end applications.

For example, he understood that gold and silver were gentler than different metals and involved them for enhancement purposes. He likewise understood that copper could be solidified by pounding and used to make apparatuses.

Metal cutting falls under the following classifications:

DRILLING

Drilling is the most common way of cutting a round opening into strong materials utilizing a drilling tool. The penetrating pieces come in various shapes and sizes, hence creating changing hollows on the metallic surfaces. The pieces pivot and press against the workpiece at a high speed. This drilling system brings about chippings from the workpiece to ultimately frame the drill openings.

They likewise integrate oils and other cutting liquids, guaranteeing smooth cutting. Other chip-shaping metals cutting cycles incorporate cutting and processing. Thrustportal

SHEARING

Shearing has existed since the Bronze Age as scissors that worked physically. It involves cutting a metal without utilizing heat and without the development of chips.

Shearing includes involving cutting sharp edges in a straight or bent way. The cycle comprises making them move some portion of the edge pushing the material onto the decent partner. The two edges at the same time apply tension to the workpiece and in the long run cut it.

Other shearing techniques incorporate punching and stepping.

LASER CUTTING

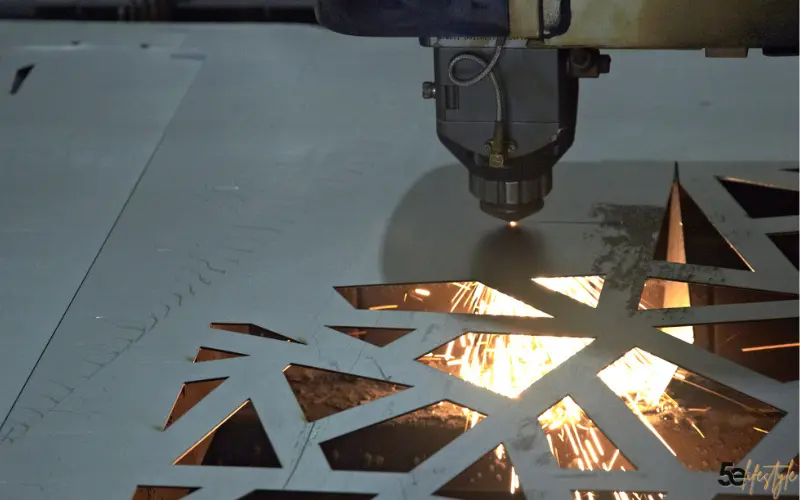

Laser cutting is a modern cutting technology that utilizes high-power laser shafts to cut into materials. Business laser machines are customized to precisely cut into metallic materials. At the point when you direct the laser bar at the metal, it either melts, blows, or consumes with extreme heat to create an ideal high-quality end plan.

The laser cutting machine was first acquainted with the diamond drilling industry in 1965. The technology was subsequently presented in metal cutting in 1967, these days these technologies are effectively found you can find many links for metal cutting on the Internet. Today, be that as it may, it is normal to find laser cutting machines utilized in different schools and private companies.

ETCHING

Etching dates back to the Middle Ages and alludes to the method involved with areas of strength for utilizing to cut into metals. Generally, goldsmiths and other metal laborers would improve metallic things like reinforces and firearms.

These men would cover a metallic plate with a corrosive safe wax, etch off the wax into the ideal theme utilizing an etching needle, and then inundate the plate with a corrosive shower. The corrosive would then “chomp” into the presented metal to create a cutting of the drawn theme. The profundity of the print relied upon the term immersion.

In present-day times, nonetheless, electroetching has been acquainted with keeping away from the results of customary etching. A portion of these incidental effects incorporates the consumption of the skin and harm to the metallic plate. Electroetching includes utilizing an electrolyte arrangement, a cathode, and an anode to etch onto the metal.

To learn more, check out the other blogs on our website: 5elifestyle