Fashion

How Are Engagement Rings Created? 3 Processes

There are two primary ways the bands on engagement rings can be formed: either casting with a mold or the more traditional handmade formation. What do the processes for band creation look like? Additionally, there are both naturally grown and lab-grown diamonds. So what does the lab growth process look like for these special gems?

Table of Contents

What Is the Ring Casting Process?

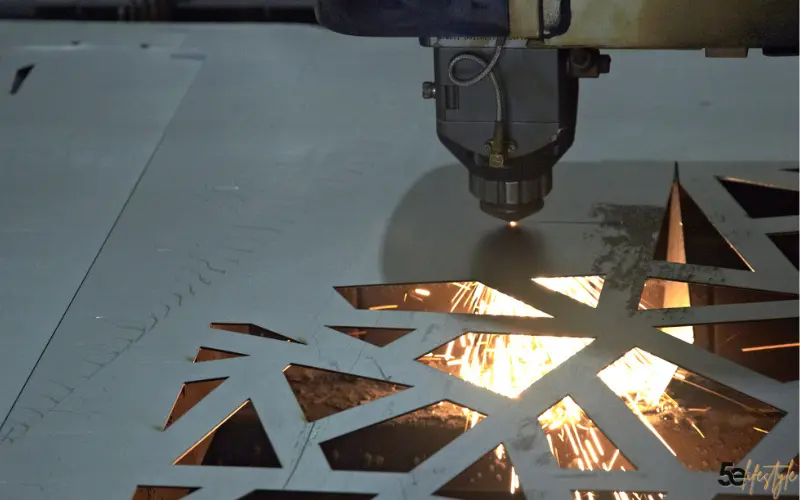

In a ring casting, generally, a wax or 3D printed version of the ring is created and then turned into a mold. In the case of wax, a craftsperson will form the shape of the band by carving it into the wax. For 3D printing, the ring band can be designed with the help of a computer and 3D printer.

According to research, these versions of engagement rings are then cased in a special kind of plaster, which eventually hardens around the original version to start creating the mold.

Once the plaster hardens, the whole piece is exposed to extremely high temperatures that destroy the original creation, leaving a cavity in its place to be filled with the metal of choice.

At this point, hot and molten metal can be poured in and put into a vacuum chamber. The vacuum prevents any air bubbles or voids from remaining inside of the band, as those may result in unattractive or non-uniform bands. Then, the ring can be polished and a diamond will be snuggly fitted for the setting.

The beauty of using a mold is that it can create and cast multiple bands with a little less work for the craftsperson, which contrasts with the hand-crafted method.

What Is the Handmade Ring Process?

The more traditional of the two processes, handmade engagement rings, start as a piece of cold-rolled metal wire. This wire bar is cut, hammered, annealed, and then polished, all by hand. Because everything is done by hand, causing a more work-intensive process, there is a bit more time and cost that must be considered.

These bands are then placed into a bending machine to create an even circle and the ends get soldered together. During soldering, flux paste may be added and removed to prevent oxidation or unevenness in the final band. Then, final adjustments will be made to the band.

From here, the setting will be created, also from a metal bar. Settings will need to fit the band exactly, and thinning can be accomplished with a hammer. A similar soldering process will follow to attach the setting to the band.

A small cup that eventually holds the diamond will then be fitted for the band, which is also soldered onto the ring. A saw may be used to create a small groove for the cup to sit.

From here, as with many engagement rings, the stone will be mounted onto the band. After the band has been secured and held in place, the stone can be added. For extra security, a special tool will be used to push down prongs that will secure the stone in its new home.

Handmade engagement rings will go through a gentler polishing and finishing process in comparison to the casted engagement rings. These will go through hot water, then be washed and touched up. Following the touch-up process, a polish may be applied to the ring, giving the final product a more attractive luster.

In both the handmade and casting process, white gold will be treated as a special case, getting coated in rhodium to make it appear as shiny as the other metals.

How Are Lab Grown Diamonds Made?

Lab-grown diamonds can be made in two different ways, both of which mimic the natural growing process of diamonds to an extent. However, both of these processes begin with a small “diamond seed,” as 1215 Diamonds calls them. This means that at least part of your lab-grown diamond may be natural, although this won’t always necessarily be the case.

HPHT

In one of these methods, called the High Pressure-High Temperature method, or HPHT, the seed is placed into a piece of carbon, which is placed onto or into some sort of press. In this process, the carbon is put under immense amounts of pressure, often over one million pounds per square inch of carbon.

At the same time, the carbon is exposed to extremely high temperatures, sometimes over 2,700 degrees Fahrenheit. These processes, combined, melt the carbon, allowing the additional diamond to form around the original seed and then be carefully cooled.

CVD

The second of these methods is called Chemical Vapor Deposition, CVD. This can use the HPHT seed, or another diamond seed as its original seed, almost continuing the original process.

This seed is then placed into another extremely hot chamber and filled with gases that are carbon-rich. These gases might include methane or hydrogen, which can be ionized into a plasma to break down the gasses’ molecular bonds.

The molecular bonds breaking down allows the original diamond seed to grow as pure carbon attaches itself to the seed. After this point, further steps may be followed to change the diamond’s color, either slightly to enhance it or dramatically to change the color altogether.

Conclusion

The engagement ring creation process can be quite complex; in fact, this is only a general overview of the crafting approach and technique. These steps will vary significantly, especially if you get any of your rings custom-made or specially crafted by an expert. Whether all of your curiosities have been satisfied or not, you now have a closer look into the nuances of engagement ring creation.

To learn more, check out the other blogs on our website: 5elifestyle